Stainless steel disc brake rotors offer superior corrosion resistance and consistent performance. They ensure reliable stopping power for vehicles.

Stainless steel, known for its durability and longevity, stands up against the harsh conditions of driving, making it an excellent material for brake rotors.

These rotors are crucial for drivers who demand high performance and safety from their braking systems.

With a high resistance to heat, stainless steel rotors maintain their structural integrity even under extreme braking scenarios. They provide a significant upgrade over standard rotors, especially for vehicles subjected to frequent stopping or inclement weather.

Opting for stainless steel disc brake rotors means investing in a component that will last longer and perform better, giving drivers peace of mind on the road.

Their rust-resistant properties also mean that they remain effective and visually appealing over time, contributing to both the aesthetics and the utility of the vehicle.

Credit: www.1motoshop.com

Introduction To Stainless Steel Disc Brake Rotors

Stainless steel disc brake rotors are essential for modern vehicles. They provide the friction surface for brake pads. This action slows down your car. These rotors are strong and resist rust. Stainless steel ensures your brakes work well in different weather.

Performance And Longevity

Stainless steel rotors offer top performance. They handle high temperatures during braking. This means they last longer than regular rotors. You get consistent stopping power and fewer replacements over time.

Comparing Materials

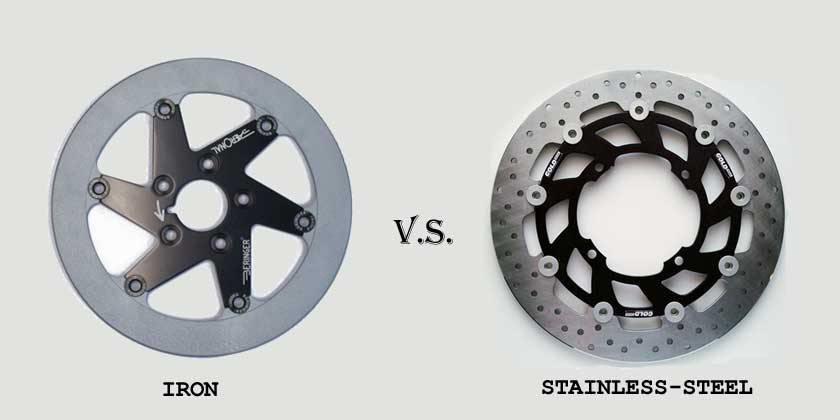

Let’s look at different rotor materials. Cast iron is common but heavy. Carbon composite is light but expensive. Stainless steel strikes a balance. It’s durable, lighter than cast iron and more affordable than carbon composite.

| Material | Weight | Cost | Durability |

|---|---|---|---|

| Cast Iron | Heavy | Low | Good |

| Carbon Composite | Light | High | Excellent |

| Stainless Steel | Moderate | Medium | Very Good |

Key Properties Of Stainless Steel

Stainless steel stands out for its unique features. It is a top choice for disc brake rotors. Let’s dive into the key properties that make stainless steel exceptional.

Corrosion Resistance

One major advantage of stainless steel is its corrosion resistance. This means it does not rust easily. Stainless steel contains chromium. Chromium creates a protective layer on the surface. This layer shields the steel from air and water. As a result, disc brake rotors last longer.

- Protects against rust

- Increases rotor lifespan

- Ensures consistent brake performance

Heat Tolerance

Stainless steel can handle high temperatures. This is crucial for disc brake rotors. During braking, rotors get very hot. Stainless steel’s heat tolerance helps in two ways:

- It prevents warping under heat.

- It maintains braking efficiency.

Together, these properties ensure safety and reliability in brakes.

The Manufacturing Process

The manufacturing process of stainless steel disc brake rotors is a blend of precision engineering and material expertise. High-quality rotors ensure safety and performance. Let’s dive into the steps involved in creating these critical components.

Material Selection

The journey begins with choosing the right stainless steel. The selected material must resist heat and corrosion. Manufacturers often opt for a high-grade alloy. This ensures durability and a long lifespan for the rotors.

Shaping And Machining

Once the material is chosen, shaping starts. Large steel sheets are cut into smaller pieces, known as blanks. These blanks then undergo a stamping process. Precision is key here to maintain the exact dimensions required for the rotors.

After stamping, machining takes place. CNC machines play a vital role in this step. They shape the rotor to its final form. Holes for ventilation and slots are added during this phase. Each rotor is checked to meet strict quality standards.

Credit: www.boattrailerparts.com

Advantages Of Stainless Steel Rotors

Stainless steel disc brake rotors stand out in the automotive world. They offer several benefits that enhance the driving experience. We will explore key advantages that make stainless steel rotors a top choice for drivers who value performance and durability.

Enhanced Braking Performance

Stainless steel rotors provide consistent braking power. Their resistance to heat helps maintain brake efficiency. This leads to shorter stopping distances and a safer ride.

- Better heat dissipation reduces fade

- Less prone to warping under high stress

- Reliable in various weather conditions

Minimal Maintenance Required

Maintenance can be a hassle, but not with stainless steel. These rotors are low maintenance and have a longer lifespan.

| Feature | Benefit |

|---|---|

| Rust Resistant | Stays clean and efficient |

| Less Wear | Longer lasting performance |

With stainless steel, you spend less time and money on upkeep. This makes for a more enjoyable driving experience and peace of mind.

Stainless Steel Vs. Other Rotor Materials

Choosing the right material for brake rotors is crucial. Stainless steel stands out among materials like cast iron and carbon ceramic. Let’s explore why.

Cost-benefit Analysis

Stainless steel rotors offer unique advantages:

- Durability: They resist rust and corrosion better.

- Performance: Consistent braking in diverse conditions.

- Cost: More affordable than carbon ceramic rotors.

Comparing costs, stainless steel provides value for money. Its lifespan and performance justify the initial investment.

Application Specific Comparisons

Not all vehicles need the same type of rotor. Let’s compare:

| Material | Best For | Not Good For |

|---|---|---|

| Stainless Steel | Everyday use, light to medium duty vehicles | Heavy-duty or racing conditions |

| Cast Iron | Heavy-duty vehicles, high performance | Cost-conscious users, corrosion resistance |

| Carbon Ceramic | High-end sports cars, racing | Everyday use, budget-friendly options |

For most drivers, stainless steel rotors strike the best balance between cost, performance, and durability.

Installation And Compatibility

Installation and Compatibility of stainless steel disc brake rotors is a straightforward process. Proper fitment and correct installation are crucial for safety. Let’s guide you through the essentials to ensure a smooth upgrade.

Vehicle Fitment Guide

Choosing the right rotors for your vehicle is vital. Start by checking the make, model, and year of your car against a fitment guide. Such guides are available from rotor manufacturers or auto parts stores.

- Consult the vehicle’s manual.

- Match the specifications with the product details.

- Verify the rotor size and type.

Installation Tips

Installing new rotors can be simple with the right tools and steps. Follow these tips for a hassle-free installation:

- Safety first: Use jack stands and wheel chocks.

- Remove the wheel to access the brake assembly.

- Take off the caliper and brake pads carefully.

- Clean the hub surface for the new rotor to sit flat.

- Align the new rotor correctly and secure it in place.

- Reassemble the caliper and pads.

- Repeat for each wheel and then perform a safety check.

Always double-check your work. Test your brakes at low speeds to ensure everything is working perfectly.

User Experiences And Reviews

Stainless steel disc brake rotors stand out in the auto parts market.

Their durability and performance speak volumes.

But what do the users say?

Real-world experiences and reviews shed light on the true value of these components.

Testimonials From Drivers

- “Switched to stainless steel rotors, and the difference is night and day.

My car stops quicker and with zero noise.”

– Jane D. - “After 20,000 miles, still performing like new.

These rotors are a game-changer.”

– Alex P. - “Worth every penny.

No rust, even in wet conditions.

Impressive longevity.”

– Mike R.

Expert Opinions

| Expert | Opinion |

|---|---|

| Emily T., Mechanic | “These rotors resist wear. Ideal for high-performance vehicles.” |

| Samuel L., Auto Engineer | “Thermal stability in stainless steel rotors prevents warping. Top choice.” |

| Lucas B., Race Car Driver | “Stainless steel delivers consistent brake feel. Trustworthy for racing.” |

Maintaining Your Stainless Steel Rotors

Stainless steel disc brake rotors demand regular care. This ensures performance and safety. Learn how to keep them in top condition with simple steps.

Cleaning Best Practices

Regular cleaning extends rotor life. Use a soft cloth and mild soap. Avoid harsh chemicals. They can damage the rotor surface. Dry thoroughly to prevent rust.

- Wipe rotors with a clean, damp cloth.

- Apply gentle soap for tough grime.

- Rinse with water carefully.

- Dry completely with a soft towel.

Inspection And Replacement Intervals

Inspect rotors during each tire rotation. Look for wear and thickness variations. Replace rotors if they show deep grooves or are too thin. Follow your vehicle’s manual for specific intervals.

| Action | Interval |

|---|---|

| Visual Inspection | With every oil change |

| Thickness Check | Every 10,000 miles |

| Replacement | As indicated by inspection |

Future Of Braking Systems

The future of vehicle safety shines bright with advancements in braking systems. Stainless steel disc brake rotors stand at the forefront of this evolution. These rotors promise enhanced performance and longer life spans. They are transforming how we think about vehicle control and safety.

Innovations In Rotor Technology

- New designs improve heat dissipation.

- Surface patterns increase friction and stopping power.

- Materials like carbon fiber enter rotor construction.

- Self-cooling mechanisms reduce wear and tear.

- Smart systems adapt to driving conditions in real-time.

The Role Of Stainless Steel

Stainless steel offers unmatched benefits in rotor technology:

| Feature | Benefit |

|---|---|

| Corrosion Resistance | Longer rotor life |

| High Strength | Resists warping under heat |

| Thermal Conductivity | Quick heat dissipation |

| Weight | Lighter than traditional materials |

| Aesthetic Appeal | Shiny and clean appearance |

Stainless steel is key for the future of safe, reliable brakes.

Credit: www.amazon.com

Frequently Asked Questions

Is Stainless Steel Good For Brake Rotors?

Yes, stainless steel is excellent for brake rotors. It resists corrosion, handles high temperatures well, and ensures consistent braking performance. This durability makes it a preferred choice for many vehicles.

What Is The Best Material For Disc Rotors?

The best material for disc rotors is typically high-carbon cast iron, offering durability and optimal heat dissipation for superior braking performance.

What Is The Best Stainless Steel For Brake Discs?

The best stainless steel for brake discs is typically AISI 420, known for its high heat resistance and durability.

What Are The Most Corrosion Resistant Brake Rotors?

Stainless steel and coated rotors offer the highest corrosion resistance. Ceramic composite rotors also excel in minimizing rust. Opting for these materials ensures long-lasting, durable brake performance in various conditions.

Why Choose Stainless Steel Disc Brake Rotors?

Stainless steel disc brake rotors offer superior corrosion resistance, ensuring long-lasting performance and durability in various weather conditions.

Conclusion

Choosing the right disc brake rotors is crucial for your vehicle’s performance. Stainless steel options offer durability and efficiency, standing out as a top choice for drivers.

Their resistance to rust and superior heat dissipation qualities make them an investment worth considering.

For safety and reliability on the road, stainless steel disc brake rotors are a clear winner.

Steven is a professional cyclist and his passion is cycling. He has been cycling for the last 6 years and he loves using bikes while outing as well. Based on his experiences with the different types of bikes; he is sharing his opinions about various bikes so that a beginner can start right away. Find him on Twitter @thecyclistguy Happy Biking.

Leave a Reply